Rolling Steel Door Repair Alvin, TX | Roll-up Door

Rolling service doors, sheet doors, and commercial roll-up doors — repaired safely, tested fully, and built to run smooth again.Open. Close. Lock. Done.

When it fails, it can stop your whole operation.

A delivery waits outside.

A bay stays exposed.

Your staff tries to “help it” and the door gets worse.

Call: +1 (281) 598-4747

If your rolling door is stuck open, call it in as urgent.

Stop Doing This (It Makes Roll-Up Doors Worse)

If the door is binding, jammed, or crooked:

- Don’t force it by hand

- Don’t keep pressing the button

- Don’t let forklifts “bump” it into place

- Don’t cut or loosen parts to “free it”

Rolling steel doors store tension and weight.

A bad move can cause damage or injury.

Types of Rolling Doors We Repair

We service common roll-up systems, including:

- Rolling service doors (metal slat doors for bays and storefronts)

- Sheet doors / rolling steel sheet doors

- Counter shutters (smaller rolling doors)

- Motor-operated roll-up doors

- Chain hoist/manual operation roll-up doors

If your door is a fire-rated rolling fire door, use this page for testing:

Fire Door Inspection & Drop Testing

Signs You Need Rolling Steel Door Repair Alvin

You don’t need to guess. These are clear warning signals:

- Door won’t open or won’t close

- Door stops halfway or reverses

- Door scrapes inside the guides

- Door jumps or shudders when moving

- Bottom bar looks bent or not sealing

- Slats look dented or “wavy”

- Motor runs but door doesn’t move

- Chain hoist feels rough or locks up

- You hear grinding or metal-on-metal noise

If the door is stuck open, treat it as a security issue.

| What you see | Likely cause | What we do |

|---|---|---|

| Door stuck halfway | guide bind, slat damage, operator limits, tension issue | stabilize, correct alignment, repair components, retest |

| Door scrapes / grinds | bent guides, debris, slat damage | clean/repair guides, correct path, replace damaged sections if needed |

| Motor runs, door doesn’t move | door jam, drive issue, disconnect, severe resistance | diagnose safely, restore smooth travel, then verify operator |

| Door closes uneven | bottom bar damage, misalignment, guide issues | correct seating, repair bottom bar/guides, full-cycle testing |

| Chain hoist hard to pull | binding, wear, tension issue | inspect mechanism, correct resistance, verify safe operation |

Bottom bar damage

Often caused by:

- forklift or pallet impact

- the door closing onto an obstruction

- misalignment that makes the door land uneven

Motor/operator problems

Often caused by:

- door resistance (the motor is “fighting” friction)

- limit setting issues

- control or wiring faults

- worn drive components

Big rule: Fix the door movement first, then the motor settings.

Common Rolling Steel Door Problems (And What Usually Causes Them)

Door jammed in the guides

Often caused by:

- guide misalignment

- bent guides

- debris buildup

- damaged slats

- door forced while crooked

Door won’t roll smoothly onto the barrel

Often caused by:

- slat damage

- barrel/tension issues

- wrong alignment after impact

- wear in key mounting points

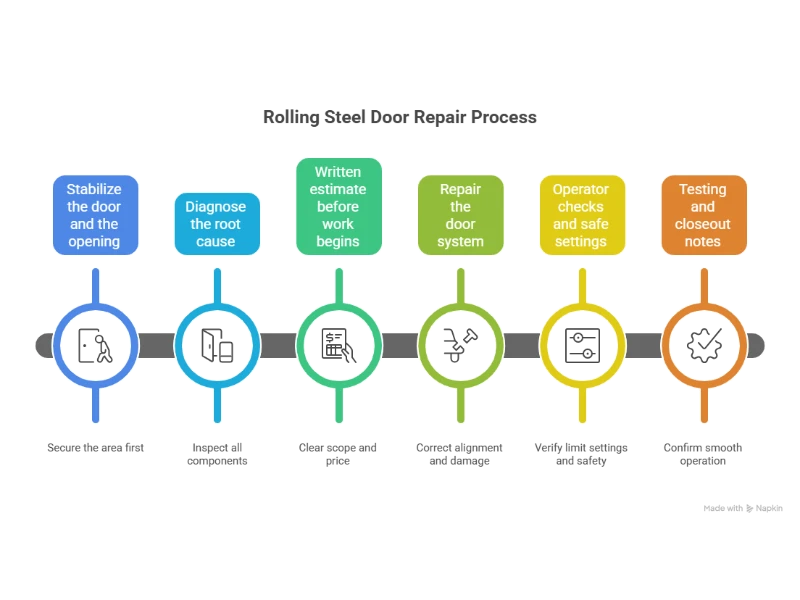

Our Rolling Steel Door Repair Process

We keep it safe and structured.

Step 1: Stabilize the door and the opening

We secure the area first.

If the door is stuck open, we focus on closing/secure options safely.

Step 2: Diagnose the root cause

We inspect:

- curtain/slats and bottom bar

- guides and alignment

- mounting points and brackets

- operator (motor) and controls

- manual chain hoist (if installed)

- door travel path and resistance points

Step 4: Repair the door system

We correct:

- alignment

- binding points

- damaged components

- unsafe mounting or loosened hardware

Step 6: Testing and closeout notes

We run repeated cycles and confirm:

- smooth travel

- stable guide movement

- secure bottom seal contact

- no grinding

- predictable operation

Step 3: Written estimate before work begins

Clear scope. Clear price. Clear options.

Step 5: Operator checks and safe settings

After the door runs smoothly, we verify:

- limit settings

- safety behavior (where applicable)

- consistent open/close performance

Repairs We Commonly Perform on Rolling Steel Doors

Depending on the issue, we can handle:

- guide alignment and repair

- bottom bar repair/replacement

- slat/curtain repair (when feasible)

- correcting door bind and resistance

- tightening and reinforcing mounts

- operator troubleshooting (after movement is corrected)

- chain hoist troubleshooting and operation checks

If your facility also needs bay door help beyond roll-ups:

Commercial Overhead Repair

Preventive Maintenance (This Saves Money on Roll-Up Doors)

Rolling steel doors live on friction and alignment. Small drift becomes big damage.

Simple maintenance that prevents breakdowns

- keep guides clear of debris

- watch for new scrape marks (early warning)

- address bottom bar damage immediately

- schedule periodic inspections for high-use doors

- stop forcing the door when it feels “off”

You can also set up a regular plan:

Commercial Door & Dock Services

Rolling Steel Door Repair FAQs

Ready to Get Your Roll-Up Door Moving Again?

For Rolling Steel Door Repair in Alvin, TX.

Tell us what’s happening: stuck open, jammed, scraping, motor runs but no movement, or impact damage. We’ll route the right service fast.