Dock Leveler & Equipment Repair Alvin, TX

Keep trucks moving, reduce downtime, and protect your team with fast, safe dock service.When it fails, loading becomes slow, unsafe, or impossible.

Forklifts can’t cross smoothly.

Pallets catch on gaps.

Crews start improvising.

That’s when injuries and damaged product happen.

This page covers the most common dock leveler problems, what to do first, how we repair levelers safely, and how to reduce repeat breakdowns.

If Your Dock Leveler Is Unsafe, Pause That Bay

If the leveler is stuck, dropping fast, or not supporting weight properly, do not “work around it.”

Do this right now

- Stop using the bay if the lip won’t seat correctly or the deck feels unstable.

- Keep personnel and equipment clear of pinch points and the pit area.

- If possible, route receiving/shipping to another door.

- Call and tell us:

- leveler type (hydraulic / mechanical / air-powered) if known

- symptom (“won’t raise,” “lip won’t extend,” “won’t store,” “drops,” “leaking fluid”)

- whether the bay is down and blocking shipments

A fast, correct repair prevents bigger damage and reduces liability risk.

Leveler drops too fast or feels unstable

- hydraulic leak

- worn seals

- structural wear in key points

- unsafe support behavior

Leveler won’t return to stored position

- spring tension issues (mechanical units)

- control and timing problems

- obstructions in the pit

- worn linkages

Excessive noise, grinding, or jerking

- worn hinges and pivot points

- poor alignment

- loose hardware

- debris buildup in the pit

Common Dock Leveler Problems We Repair

Dock failures are usually predictable. Here are the problems we see most often.

Dock leveler won’t raise or lift

- hydraulic or power issue

- worn components in the lift system

- mechanical binding in the pit area

- unsafe operation due to damaged parts

Lip won’t extend or won’t stay extended

- lip mechanism wear

- hinge point damage

- alignment or control issues

- hydraulic faults (on hydraulic units)

Visible hydraulic fluid leaks

Hydraulic leaks are a “fix it now” problem. Leaks get worse quickly and can turn into a complete failure.

Dock Equipment We Repair

Dock equipment keeps the bay safe and efficient. When these fail, the leveler may still work—but the bay becomes risky, leaky, or hard to use.

Dock seals & dock shelters

These reduce air gaps, improve comfort, and protect product.

Common issues

- torn curtains or worn pads

- bent frames

- gaps around the trailer

- water and dust intrusion

What we do

- replace worn seal components (where applicable)

- secure loose frames and hardware

- correct fit problems that create gaps

Vehicle restraints (if installed)

These reduce trailer creep and help keep loading safer.

Common issues

- restraint won’t engage or release

- inconsistent sensor behavior

- damage from impacts

- control issues

What we do

- diagnose safe operation and controls

- repair/replace damaged components where feasible

- verify correct function before returning the bay to service

If you’re not sure what counts as “dock equipment,” just describe what’s failing at the bay (seal, bumper, restraint, plate, light area, etc.). We’ll identify it onsite.

Safety legs / toe guards / pit safety items (where applicable)

Dock safety parts often get ignored until they fail.

Common issues

- bent guards

- missing fasteners

- unsafe gaps and pinch points

What we do

- restore safe barriers and secure hardware

- note high-risk issues clearly for management

Dock bumpers

Bumpers protect your building and help trailers seat correctly.

Common issues

- missing or crushed bumpers

- uneven impact points

- trailers hitting the wall or door frame

What we do

- replace worn bumpers

- correct mounting and alignment so impact lands where it should

Dock plates / edge-of-dock plates

When the bridge plate is damaged, forklifts take a beating.

Common issues

- bent plate

- hinge wear

- unsafe gaps or shifting

What we do

- inspect seating and hinge points

- repair/replace as needed to restore safe crossing

Mechanical dock levelers

- rely on springs and mechanical linkages

- issues often involve worn parts, spring fatigue, and mechanical binding

Air-powered levelers

- air bag / air system issues

- controls and sealing problems

- alignment and wear points like other systems

No matter the type, the goal is the same: safe, stable, predictable dock bridging.

Dock Leveler Types We Work On

If you’re not sure what you have, that’s fine. We can identify it quickly onsite.

Hydraulic dock levelers

- smooth operation

- common in busy bays

- most issues relate to hydraulics, valves, hoses, cylinders, or controls

Mechanical dock levelers

- rely on springs and mechanical linkages

- issues often involve worn parts, spring fatigue, and mechanical binding

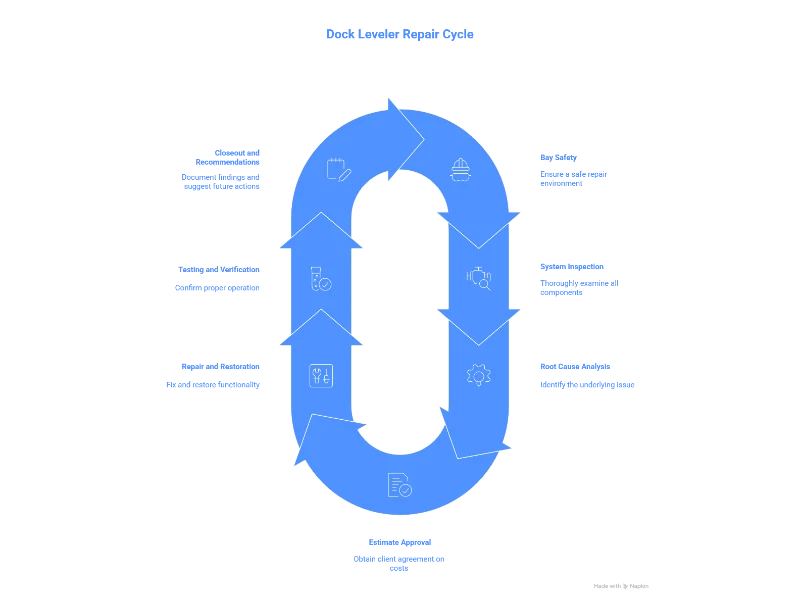

Our Dock Leveler & equipment Repair Alvin Process (Step-by-Step)

Step 1 — Bay safety and controlled access

We coordinate with your supervisor to control traffic through the area.

Step 2 — Inspect the full system

We inspect:

- deck and lip condition

- hinge and pivot points

- frame and pit mounting

- lift mechanism and operating path

- hydraulics (if applicable): hoses, cylinders, valves, fluid condition

- controls and safety features

- dock equipment: seals/shelters, bumpers, restraints, plates (if present)

Step 4 — Written estimate before work begins

Clear scope. Clear parts. Clear labor. No guessing.

Step 5 — Repair and restore safe function

We repair or replace worn or failed components and restore stable operation.

Step 6 — Testing and functional verification

We confirm:

- smooth raise/lower

- correct lip operation

- stable support and seating

- safe stored position

- consistent operation through repeated cycles

- bay protection equipment is secure and functional

Step 3 — Identify the root cause (not just the symptom)

A leveler “not lifting” may be:

- hydraulic issue

- mechanical bind

- worn pivot points

- control fault

- pit obstruction

A bay issue may also be equipment-related:

- bumper failure causing bad trailer positioning

- seal damage causing exposure and product risk

- restraint failure creating unsafe trailer movement

We confirm the cause before any repair starts.

Step 7 — Closeout notes + next-step recommendations

We summarize what failed, what we fixed, and what to watch next.

Why Dock Leveler Repairs Need Pros (Not Quick Fixes)

Dock equipment has:

- heavy loads

- pinch points

- moving steel components

- lift forces

- real injury risk if something shifts unexpectedly

A “temporary solution” might keep a bay moving for an hour, but it can create:

- bigger mechanical damage

- forklift incidents

- worker injury exposure

- product loss

- liability issues

We repair dock levelers with a safety-first approach: stabilize, diagnose, repair correctly, and test under safe conditions.

| What your team sees | Likely cause | What we typically do |

|---|---|---|

| Leveler won’t rise | hydraulic/power issue, mechanical bind | diagnose system, correct lift fault, clear binding |

| Lip won’t extend | lip mechanism wear, control issue | repair lip linkage/hinge points, correct control behavior |

| Leveler drops fast | leak or seal failure | repair hydraulics, restore stable lowering |

| Won’t store properly | linkages, springs, obstruction | correct mechanism, clear pit, adjust system |

| Grinding/jerking | pivot wear, loose hardware | replace/repair wear points, tighten and align |

| Trailers hit building / gaps stay open | bumper or seal/shelter failure | replace bumpers or repair seal/shelter fit |

| Trailer feels unstable at dock | restraint issue or seating problem | restraint issue or seating problem |

What Affects Cost?

Dock system varies by size, type, and site setup.

Main cost factors

- leveler type (hydraulic / mechanical / air-powered)

- severity of the issue

- parts needed (hoses, seals, cylinders, linkages, hinges, controls)

- dock equipment needs (bumpers, seals/shelters, plates, restraints)

- access and bay conditions

- number of bays if you’re servicing multiple units

You’ll get a written estimate with clear scope.

What Causes Dock Leveler Problems Over Time?

Most leveler failures come from:

- heavy daily cycles

- lack of lubrication at pivot points

- debris buildup in pits

- hydraulic fluid issues (leaks, contamination)

- impact damage from forklifts/pallet jacks

- loose hardware and worn hinge points

A little maintenance prevents most of the “worst day” failures.

Preventive Maintenance for Dock Levelers & Dock Equipment (Worth It)

A repair gets you running again. Maintenance keeps you predictable.

What a maintenance visit focuses on

- inspect deck, lip, and hinge wear

- check frame integrity and mounting

- clean and clear pit debris

- verify smooth movement

- inspect hydraulics: leaks, hoses, cylinders, fluid condition

- check controls and safety behavior

- inspect bumpers, seals/shelters, and restraint condition (if present)

- tighten and secure hardware

If your facility runs shipments daily, preventive maintenance reduces downtime and emergency calls.

How Long Does Dock Leveler Repair Take?

Time depends on the fault and parts availability, but many repairs can be completed efficiently once the cause is confirmed.

Typical scenarios

- Minor adjustments / obstruction issues: often same visit

- Hydraulic repairs: depends on leak location and part replacement

- Structural wear repairs: may take longer due to heavy components

- dock equipment replacements (bumpers/seals): often straightforward once parts are confirmed

We’ll give you a clear timeline after diagnosis and keep your team updated.

Related Commercial Services

Facilities that need dock leveler repair often also need: