Commercial Overhead Door Repair Alvin, TX

Keep your bay doors moving, your crews working, and your site secure — with fast, safe, documented repairs.Trucks wait.

Staff loses time.

Shipping schedules slip.

Security becomes a problem the moment a door won’t close.

This page covers the common failures, what to do first, how we repair doors safely, and how to reduce downtime with maintenance and smart upgrades.

If Your Overhead Door Is Stuck Open, Treat It Like a Security Issue

A bay door stuck open isn’t just inconvenient. It’s exposure.

Do this right now

- Stop running the operator if the door is binding, crooked, or jerking.

- Keep people clear of the door opening and tracks.

- If you can, pause operations at that bay and route traffic to another bay.

- If the door is partially open and unstable, don’t walk under it.

- Call and tell us:

- door type (sectional / rolling steel / high-speed, etc.)

- operator type (chain hoist, jackshaft, trolley, etc.)

- symptom (“won’t close,” “cable hanging,” “motor hums,” “off track”)

Commercial operators and controls

- Wall-mounted jackshaft operators

- Trolley operators

- Hoist systems

- Push-button stations, key switches, safety devices

If you’re not sure what you have, send a quick photo. It speeds diagnosis and parts matching.

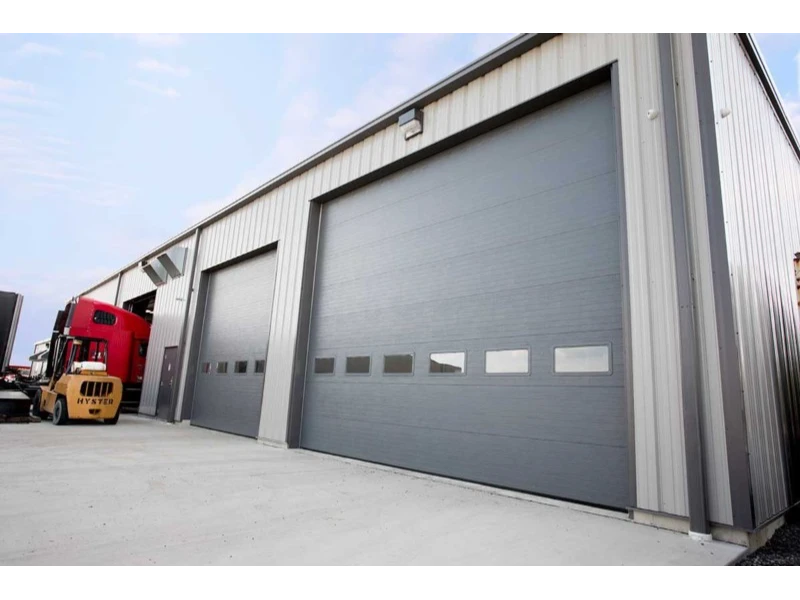

Types of Commercial Doors We Repair

Every site is different. We work on common commercial systems including:

Sectional overhead doors

- Steel sectional doors for bays and warehouses

- Insulated or non-insulated panels

- Standard lift, high lift, and vertical lift setups (where applicable)

Rolling steel doors

- Rolling service doors

- Sheet doors / rolling doors

- Slats, guides, barrels, and bottom bars

Common Commercial Overhead Door Problems We Fix (Alvin, TX)

Door won’t open or won’t close

- Operator runs but door doesn’t move

- Door stops mid-travel

- Door closes then reopens

- Door won’t respond to controls

Door is off-track or crooked

- One side higher than the other

- Rollers popped out

- Door binds hard at the bottom or mid-track

- Door won’t respond to controls

Related page: off track

Noisy, shaking, or rough travel

- Worn rollers, hinges, tracks

- Loose mounts

- Door rattles under movement

Related page: roller track

Dock-area problems (often connected)

If the door is fine but the dock flow is broken, the issue might be the dock equipment.

Related page: dock leveler dock equipment

Cables, drums, and bottom bracket failures

- Cable hanging loose

- Door lifts unevenly

- Loud snap or sudden drop feeling

Related page: cable drum bottom bracket repair

Spring and counterbalance issues

- Door feels heavy

- Operator strains or trips

- Loud bang (spring break)

Related page: spring repair

Rolling steel door issues

- Curtain won’t roll smoothly

- Door jams in guides

- Bottom bar damage

- Slat damage or misalignment

Related page: rolling steel

| What your team sees | Likely cause | What we typically do |

|---|---|---|

| Operator runs, door doesn’t move | Broken spring/cable, disengaged drive, gear issue | Secure door, diagnose lift system + operator, repair and test |

| Door stops halfway every time | Binding track/rollers, limit settings, safety device issue | Correct friction first, then set limits safely |

| Door lifts crooked | Cable/drum issue, track shift, roller failure | Stabilize door, reset cables/drums, align track, replace worn parts |

| Loud grinding / scraping | Roller/track damage, guide issue (rolling steel) | Repair/replace rollers/track/guides, tighten mounts |

| Door won’t close / reverses | Safety device, obstruction, door resistance | Clear path, test safety devices, remove resistance, re-test |

| Door shakes hard under load | Loose hardware, worn hinges/rollers | Replace worn parts, tighten and reinforce mounting points |

What Makes Commercial Repairs Different (Why “DIY” Costs More Later)

Commercial doors are heavier, used more often, and carry more risk.

A “quick workaround” can:

- damage tracks and panels

- burn out operators

- cause off-track events

- create safety hazards for staff

We repair commercial doors with a safety-first approach:

- stabilize the door

- correct the root cause

- restore smooth travel

- test the full cycle

- document the work if needed for managers or compliance

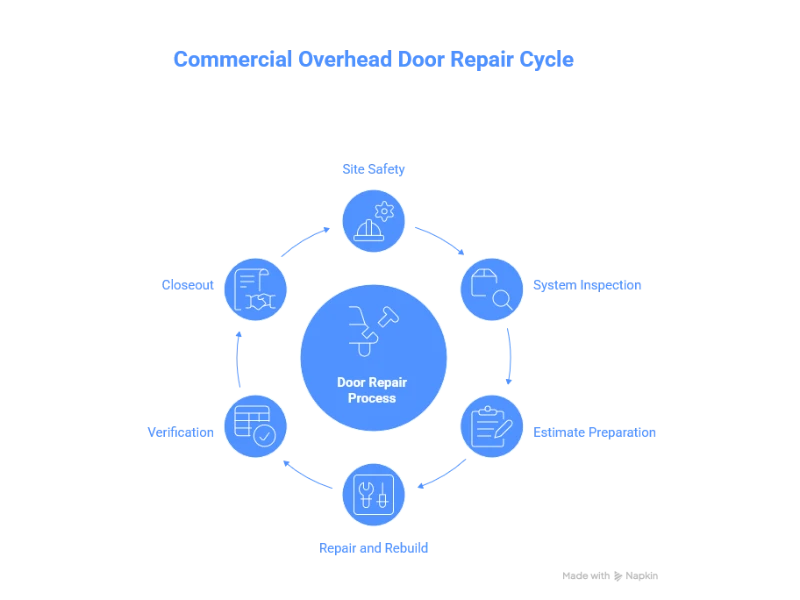

Our Commercial Overhead Door Repair Alvin Process

Step 1 — Site safety and stabilization

We secure the door and make the area safe for staff and traffic.

Step 2 — Full system inspection

We inspect:

- tracks and roller paths

- hinges, brackets, and mounting points

- cables, drums, bottom brackets

- spring/counterbalance system

- operator drive, controls, safety devices

- door alignment and travel consistency

Step 3 — Written estimate before repairs

Clear scope. Clear price. Clear options.

Step 5 — Operator and safety verification

We test:

- open/close cycles under normal use

- stopping behavior

- safety devices

- smooth travel and full seal

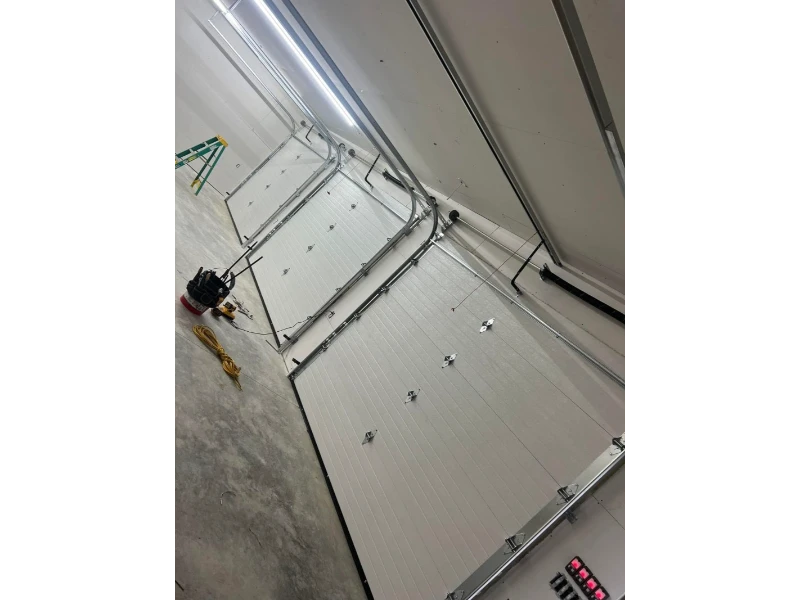

Step 4 — Repair and rebuild the movement system

We don’t just “get it moving.” We make it stable:

- correct alignment

- correct tension

- corrected mounts

- replaced worn components

Step 6 — Closeout notes and practical recommendations

You get a simple summary:

- what failed

- why it failed

- what we replaced

- what to watch next

- suggested maintenance interval

Spring/counterbalance correction

- Correct sizing and balancing

- Replacement when broken or worn

- Balance test so the operator isn’t forced to “lift weight”

Operator troubleshooting

- Control station issues

- Wiring faults

- Drive chain/belt issues

- Limit and force adjustments (only after door moves smoothly)

Repairs We Commonly Perform for Commercial Sites

Track and hardware repairs

- Track realignment and reinforcement

- Replacement of bent track sections

- Tightening and securing loose brackets

- Upgrading worn hardware where needed

Roller and hinge replacement

- Worn rollers cause friction and operator strain

- Loose hinges create door “play” and instability

- Replacing these early prevents off-track incidents

Cable and drum service

- Re-wrap and correct drum alignment (when safe)

- Replace frayed cables

- Correct uneven tension and crooked travel

Downtime Control: How We Help You Keep Operations Moving

Commercial clients usually care about two things:

- speed

- repeat reliability

How we reduce repeat failures

- Fix root causes (alignment + balance + worn parts)

- Replace “about-to-fail” components when it makes sense

- Recommend a simple maintenance rhythm

- Keep your doors running smooth so operators don’t get abused

Scheduling options (practical for businesses)

- Early/late windows when possible

- Priority response for stuck-open doors

- Plan repairs around shipping schedules when feasible

Best practice (simple recommendation)

- Quarterly checks for busy bays

- Biannual or annual checks for lower-use doors

- Immediate inspection after any impact (forklift bump, truck contact, etc.)

Preventive Maintenance for Commercial Doors (Worth It)

Commercial doors work hard. Maintenance keeps them predictable.

What a commercial door tune-up focuses on

- hardware tightening

- roller/hinge wear inspection

- track alignment check

- cable condition check

- spring balance evaluation

- operator function and safety device test

Related page: door tune-up

Special Note: Fire-Rated Doors and Compliance Work

If your site has fire-rated doors, inspections and testing may be required depending on your facility and local requirements.

We can coordinate:

- inspection support

- operational testing

- documentation for management

Related page: fire door inspection drop test

(If you tell us your facility type and door type, we’ll guide you to the right service.)

Service Areas Around Alvin (Commercial Coverage)

We serve Alvin and nearby business corridors and surrounding communities, including:

Nearby cities we commonly serve

- Pearland

- Manvel

- Friendswood

- Santa Fe

- League City

- Texas City

- Dickinson

- Webster

If your facility sits near a main route like Hwy 6 or Hwy 35, we’re used to working around real traffic and real schedules.