Automatic & manual gate repair Alvin, TX

Automatic & manual gate repairs for homes and businesses — safe, reliable, and done right the first time.When it fails, you lose both convenience and security.

The gate won’t open.

It stops halfway.

It drags on the ground.

It opens—but won’t close behind you.

Or it makes that grinding sound that tells you something is about to snap.

This page covers the most common gate problems, what causes them, what we repair, and how to prevent repeat breakdowns.

If Your Gate Is Stuck Open, Treat It Like a Security Issue

A gate stuck open exposes your property. A gate stuck halfway can also be a safety hazard.

Do this right now

- Stop pressing the remote if the gate is jerking, grinding, or stopping hard..

- Keep kids and pets away from the moving area.

- Don’t try to “push it through” if it’s binding—this often bends hardware or burns out the operator.

- If the gate is open and won’t close, secure valuables and call for service.

When you call, tell us:

- gate type: swing or slide

- manual or automatic

- symptom: won’t open / won’t close / stops / drags / noisy / remote not working

Automatic gates (operator-driven)

- Gate motor/operator issues

- Remotes and keypads

- Sensors and safety devices

- Wiring and control troubleshooting

If you’re not sure what you have, a photo helps. Most problems can be identified quickly from the gate layout.

Types of Gates We Repair (Residential + Light Commercial)

Swing gates

- Single swing

- Dual swing

- Heavy metal swing gates (common on driveways)

Sliding gates

- Track slide gates

- Cantilever slide gates

Manual gates

- Hinges, latches, rollers, wheels, tracks, posts

Common Gate Problems We Fix in Alvin

Gate won’t open or won’t close

- power issue

- remote/keypad problem

- control board issue

- motor/operator issue

- safety sensor triggered or misaligned

- binding gate hardware causing resistance

Gate stops halfway or reverses

- sensor/photocell issue

- force settings reacting to resistance

- track/roller drag

- physical misalignment

Remote range is weak or inconsistent

- weak batteries

- antenna placement

- receiver interference

- programming issues

Gate drags on the ground

- hinge sag (swing gates)

- worn wheels/rollers (sliding gates)

- track issues

- post movement or foundation shift

Gate is loud or grinding

- dry hinges

- worn rollers

- loose brackets

- damaged track

- motor strain from resistance

Related page: keypad remote programming

Why Gates Fail (The Real Causes)

Most gate failures come down to one thing: resistance.

A gate motor is not meant to “fight” a dragging gate.

When the gate begins to bind, the motor and control system eventually fail.

Typical root causes

- sagging hinges or worn hinge bearings

- bent brackets and loose hardware

- debris in tracks (gravel, leaves, mud)

- misalignment from post movement or impact

- wiring wear, moisture, or corrosion

- failing control boards or operator components

- sensor issues causing false stops

Fixing the root cause prevents repeat calls.

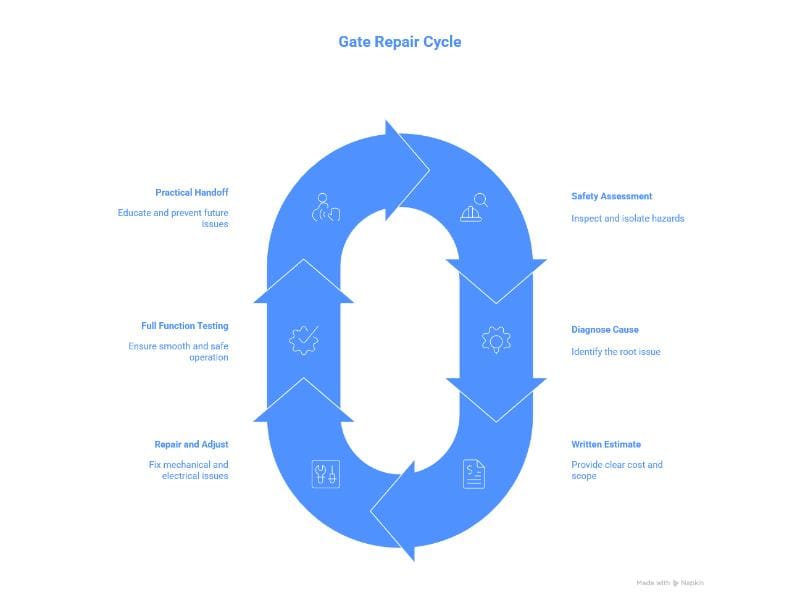

Our Automatic & manual gate repair Alvin Process (Step-by-Step)

Step 1 — Safety assessment

We inspect the gate movement path and isolate the hazard area.

Step 2 — Diagnose the real cause

We check:

- physical movement (drag, sag, misalignment)

- hardware condition (hinges, rollers, track)

- operator behavior (motor strain, stop/reverse behavior)

- sensors and controls (false triggers, wiring)

Step 3 — Written estimate before work starts

Clear scope. Clear cost. Clear options.

Step 6 — Practical handoff

We show you what caused the issue and how to prevent the next one.

Step 4 — Repair and adjustment

We correct mechanical resistance first.

Then we address operator settings and controls.

Step 5 — Full function testing

We test multiple cycles:

- smooth open and close

- consistent stops

- safe reversal behavior (if applicable)

- stable remote/keypad operation

| What you notice | Likely cause/th> | What we typically do |

|---|---|---|

| Gate won’t move at all | power/control issue or hard bind | diagnose power/controls + fix mechanical bind |

| Gate stops halfway | sensor trigger or resistance | align sensors, remove drag, adjust safely |

| Gate drags on ground | sagging hinges or worn wheels | repair hinges/wheels, realign gate |

| Gate is loud/grinding | dry/worn hardware or track issues | service rollers/hinges/track, tighten mounts |

| Remote works only close up | battery/receiver/antenna issue | replace battery, test receiver, fix signal path |

| Remote works only close up | battery/receiver/antenna issue | replace battery, test receiver, fix signal path |

| Gate opens but won’t close | sensors blocked/misaligned or settings | clear/align sensors, verify closing logic |

Automatic gate repairs (operator systems)

- operator troubleshooting (motor, gears, drive components)

- control board diagnosis

- power supply checks

- wiring and connection checks

- remote and keypad programming

- sensor alignment and safety device testing

Safety checks

We verify safe movement and stopping behavior.

A gate that closes unpredictably is a liability.

What Our Gate Repair Service Includes

We approach gate repair like a system: mechanical + electrical + safety.

Mechanical gate repairs

- hinge repair/replacement

- gate alignment and leveling

- wheel/roller replacement

- track repair and cleaning (slide gates)

- latch and stop repair

- tightening and reinforcing loose hardware

- post alignment assessment (when applicable)

Upgrading springs is one of the most practical “spend once, save later” moves in garage door repair.

What Affects Cost?

Gate repair cost depends on:

Most Common Factros

- gate type (swing vs slide)

- manual vs automatic system

- mechanical wear level (hinges/rollers/track)

- electrical/controls troubleshooting needed

- parts required

- urgency (security-related stuck-open gates)

You’ll get a written estimate before we start.

Repair vs Replacement: When Does It Make Sense to Replace Parts?

We don’t push replacements that don’t help. But some parts wear out.

Common parts that often need replacement

- gate hinges (sag, worn bearings)

- rollers/wheels (flat spots, wobble)

- track sections (bent, damaged)

- latch hardware (broken alignment)

- operator components (when gears or motor are failing)

If the gate structure itself is bent or the post foundation is unstable, we’ll explain what’s realistic and what isn’t.

How Long Does Gate Repair Take?

Most gate repairs are completed in one visit, depending on parts and severity.

Typical time range

- small adjustments and programming: 30–90 minutes

- mechanical hardware repairs: 1–3 hours

- operator diagnosis + repairs: varies based on system and components

We’ll give you a clear plan after diagnosis.

Preventive Gate Maintenance (Simple Steps That Work)

A little attention prevents big failures.

Homeowner / staff tips

- keep slide tracks clear (gravel and leaves are gate killers)

- listen for new grinding noises and act early

- don’t force the gate manually against the operator system

- replace remote batteries before they die

- avoid slamming manual gates (it loosens mounts and sags hinges)

For automatic gates

If the gate starts dragging, fix that first.

A dragging gate burns out operators fast.

Related Services

Gate repair often connects with: