Garage Door Cable, Drum & Bottom Bracket Repair in Alvin, TX

Same-day service for hanging cables, crooked doors, loud pops, and stuck garage doorsThe door starts lifting… then tilts.

One side climbs. The other side drags.

You see a cable hanging near the track.

Or you hear a sharp pop and the door slams down harder than normal.

That’s not “just a cable.” It’s your lift system losing balance.

This page explains what causes cable failures, why bottom brackets matter, how we repair drums safely, and what you can do today to avoid repeat breakdowns.

Stop Using the Door (This Is a Safety Issue)

Cables and drums operate under high tension. When something slips, the door can become unstable.

Do this right now

- Stop pressing the opener button. Cycling it can twist the door and worsen damage.

- Don’t pull the emergency release if the door is crooked or stuck halfway. The door can drop.

- Keep kids and pets away from the door opening and tracks.

- If the door is stuck open, don’t stand under it.

If you need to get out and the door is stuck

Call us and tell us:

- Is the door half open or fully closed?

- Is one cable hanging loose?

- Did you hear a bang (possible spring issue too)?

We’ll guide you on the safest next step.

Bottom bracket warning signs

- Bottom corner looks loose

- Rusted or bent bracket near the bottom roller

- Cable end looks mis-seated or pulling at an angle

If you see any of this, stop. The lift system needs a reset and a proper tension setup.

Signs You Need Cable, Drum, or Bottom Bracket Repair

These issues often look like “the door went weird.” Here are the real signs:

Cable-related warning signs

- Cable is frayed, rusty, or has broken strands

- Cable is hanging down near the track

- Door rises crooked (one side higher)

- Door makes a grinding sound near the top corners

- Door closes but looks twisted and won’t seal evenly

Drum-related warning signs

- Clicking or snapping sound near the torsion tube

- Cable looks like it’s stacking incorrectly on the drum

- You see slack cable on one side after the door closes

- Door stops mid-travel without a clear obstruction

What These Parts Do (Simple Explanation, No Jargon)

A garage door doesn’t lift because the opener is “strong.”

It lifts because the springs and cables carry the weight.

Lift cables

Steel cables connect from the bottom corners of the door up to the drums. They pull the door evenly from both sides.

Drums

Drums sit on the torsion tube above the door. When the door moves, the drums wind and unwind the cable like a reel.

Bottom brackets

Bottom brackets anchor the cable at the bottom of the door. They also hold the bottom roller and take real load during movement.

If any of these parts slip, the door loses balance. That’s when doors go crooked, rollers pop out, and tracks bend.

Why Cables Slip or Snap in Alvin Homes

Cables don’t usually fail “for no reason.” Something adds strain over time.

The most common causes we see

- Worn springs (weak spring = extra strain on cables and drums)

- Door out of balance (door weight not supported evenly)

- Worn rollers that drag and jerk the door

- Loose track brackets that let the door shift sideways

- Rust and humidity (Alvin’s weather accelerates corrosion)

- Old cables with broken strands you didn’t notice

- Improper past repair (wrong cable routing, drums not set evenly, sloppy tension)

Many cable calls also involve one of these service pages:

“Cable Repair” Is Not Just Replacing a Cable

Some companies replace a cable and leave.

That’s how the door comes back crooked again.

A proper cable/drum/bottom bracket repair restores:

- correct cable tension on both sides

- correct drum alignment

- stable track travel

- balanced door movement

- safe opener operation

If you only replace a cable without correcting the cause, the new cable gets abused and fails early.

| What you notice | Most likely issue | What we do |

|---|---|---|

| Door lifts crooked | Cable tension uneven / drum slip | Secure door, reset drums, correct cable tension |

| Cable hanging on one side | Cable off drum or broken | Replace cable(s), reset drum alignment |

| Door jerks near the top | Cable stacking wrong on drum | Re-seat cable, correct drum grooves, test full cycle |

| Bottom corner looks loose | Bottom bracket damage | Repair/replace bracket, re-anchor cable safely |

| Door came off track after cable issue | Cable failure caused twist | Off-track reset + cable/drum correction |

What You’ll Usually See During This Repair (So Nothing Feels Mysterious)

Common parts we replace on cable/drum jobs

- Lift cables (frayed, stretched, snapped)

- Drums (worn grooves, cracks, misalignment)

- Bottom brackets (rusted, bent, damaged cable anchor)

- Rollers (worn rollers cause drag and derailments)

- Hinges or track brackets (if loosened by the imbalance)

You’ll get a written estimate that lists what’s needed now vs what can wait.

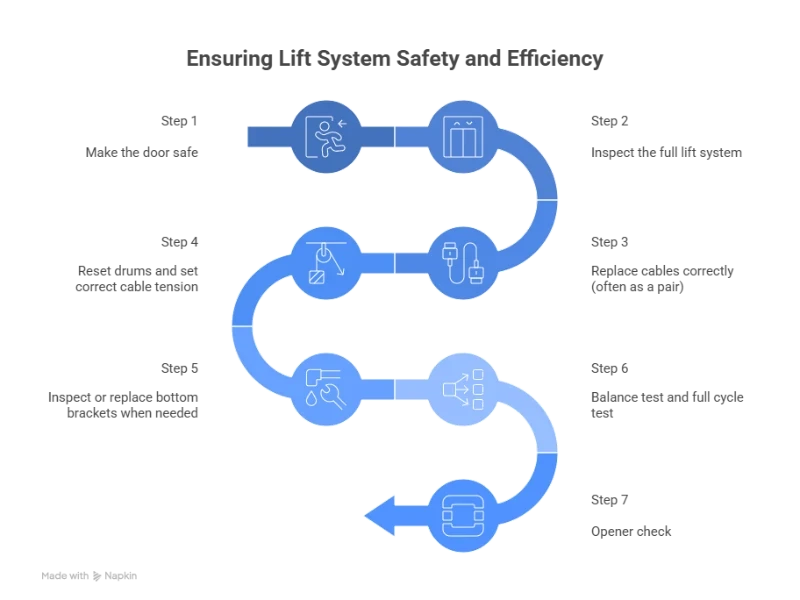

Our Cable, Drum & Bottom Bracket Repair Process

Step 1: Make the door safe

We secure the door so it cannot fall or twist more.

Safety comes first. Always.

Step 2: Inspect the full lift system

We check:

- spring condition and balance

- cable condition on both sides

- drums for wear, cracks, or misalignment

- bottom brackets and attachment points

- track alignment and roller condition

Step 3: Replace cables correctly (often as a pair)

If one cable failed, the other is often worn too.

Replacing both usually keeps tension equal and prevents uneven lift.

Step 6: Balance test and full cycle test

We test the door by hand first.

Then we run full open/close cycles and confirm smooth travel.

Step 7: Opener check

A twisted door strains the opener.

After we correct the lift system, we confirm the opener runs clean and stable.

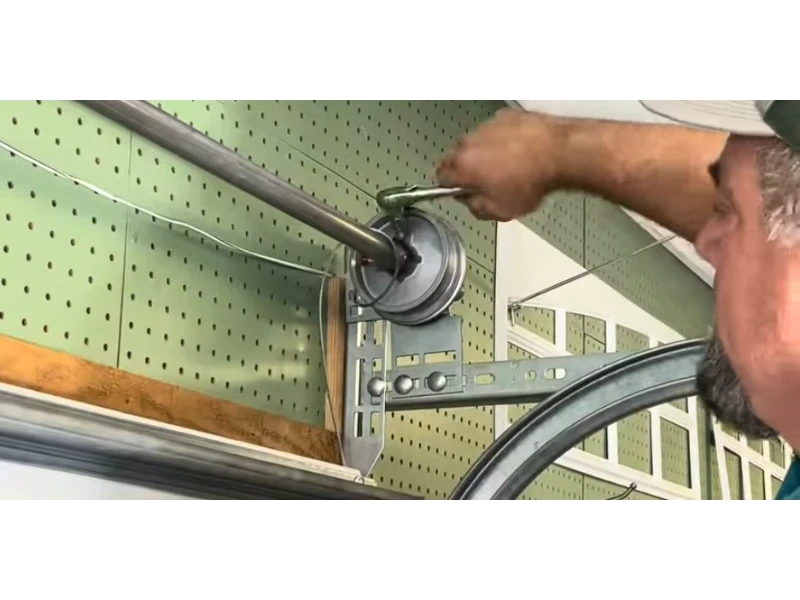

Step 4: Reset drums and set correct cable tension

This step matters more than people think.

We align the drums so cables spool evenly and don’t climb into the wrong groove.

Step 5: Inspect or replace bottom brackets when needed

Bottom brackets take load and can rust or deform.

We fix bracket issues before putting tension back on the system.

Repair vs Replacement: When Does It Make Sense to Replace Drums or Brackets?

Sometimes a repair is enough. Sometimes the safer move is replacement.

We recommend replacement when:

- Drums show visible wear or cracks

- Grooves are damaged and cables won’t track clean

- Bottom brackets are rusted, bent, or pulling away

- The system has repeat cable issues (usually from worn hardware)

Replacing a compromised bracket is not “upselling.” It’s preventing a sudden drop later.

How Long Does Cable/Drum/Bracket Repair Take?

Most jobs are completed in one visit.

Typical time range

- Standard cable replacement + drum reset: often 1–2 hours

- More time needed if: the door is off-track, tracks are bent, springs are failing, or bottom hardware is heavily rusted

If the problem ties back to a worn spring, we may recommend spring service on the same visit. That prevents the next failure.

What Affects the Cost?

Pricing depends on door size and how far the problem spread.

Main cost factors

- Single vs double door (weight and cable length)

- One cable vs both cables

- Drum condition (reset vs replace)

- Bottom bracket condition (repair vs replace)

- Any track/roller damage caused by the twist

- Emergency / after-hours service needs

What you should expect from a fair estimate

- Scope in writing

- Parts listed clearly

- Testing included

- Practical advice on what to fix now vs later

Alvin-Specific Scheduling Note (Real Life)

On busier local weekends—like Frontier Day events hosted at National Oak Park—calls can spike and traffic can slow down. Rotary Club of Alvin+1

Seasonal traffic increases around Froberg’s Farm can also affect arrival windows on Hwy 6. Froberg’s Farm

If your door is stuck open or hanging crooked, call early. That’s the fastest way to get the door secured.

How to Prevent Cable and Drum Problems (Simple Habits That Work)

You don’t need to be handy. You just need to catch issues early.

Watch for these early warnings

- Door begins lifting unevenly

- New grinding or clicking near the top corners

- Cable looks slightly slack when the door is closed

- SRollers wobble or squeal

- Door shakes during closing

Do these basic steps

- Keep tracks clear of debris (don’t grease the track itself)

- Listen for new sounds and stop using the door if it looks crooked

- Schedule an annual tune-up

Avoid these habits

- Don’t keep pressing the opener when it struggles

- Don’t “help” the door by pulling it while the opener runs

- Don’t ignore frayed cable strands (they don’t get better)

Related Services

Cable and drum issues often connect to other repairs. Link these from this page:

- Broken spring repair & replacement

- Off-track repair

- opener repair

- Roller & track repair

- Emergency repair

This helps users find the right next step and strengthens topical coverage for search.