Fire Door Inspection & Drop Test Alvin, TX

Protect lives, protect property, and stay ready for audits with documented, professional service.They’re a life-safety system.

When a fire door doesn’t close fully, doesn’t latch, or drops too fast (or not at all), it can fail at the exact moment it’s needed most. That puts people at risk, increases property damage, and creates compliance problems during inspections.

If your facility is in Alvin (77511 / 77512)—near Highway 6, Hwy 35, industrial routes, or commercial corridors—this service is built for safety, reliability, and clear reporting.

What is fire door inspection & Drop Test Alvin?

Fire door inspection

A structured check of the fire door assembly to confirm it’s in safe working condition and operates as intended.

Drop testing

A controlled test of the door’s release and closing function to confirm the door can close correctly in a fire event scenario (and do so safely).

In simple terms:

We verify that the door can close and protect the opening the way it’s supposed to.

Who Needs Fire Door Testing in Alvin?

This service is typically required or strongly recommended for facilities such as:

- Warehouses and distribution sites

- Manufacturing and light industrial facilities

- Auto and service centers

- Storage facilities

- Commercial buildings with fire-rated openings

- Sites with rolling fire doors connected to alarm/safety systems

If you have rolling fire doors or fire-rated assemblies, regular inspections and testing help you avoid last-minute failures during audits and keep your site safer every day.

Common Issues We Find (And Fix)

Fire doors often fail for simple reasons—until they aren’t simple anymore.

Typical problems

- Door doesn’t fully close or stops early

- Door doesn’t latch properly

- Door closes but binds in the guides

- Damaged slats/curtain, bent bottom bar, or misalignment

- Obstructions in the path

- Worn guides or loose mounting points

- Release mechanism issues (won’t release, releases unexpectedly, inconsistent behavior)

- Door drops too fast or too slow (unsafe or non-functional behavior)

If a door fails a test, we don’t just note it—we explain the cause and the safest way to correct it.

Why Drop Testing Matters (Real-World Benefits)

- Safety: A fire door that won’t close is a risk. Full stop.

- Compliance readiness: Inspections are easier when you have clear records and a door that performs properly.

- Preventive savings: Small issues—like guide misalignment or hardware loosening—can turn into major repairs if ignored.

- Reduced downtime: Fixing issues early avoids emergency shut-down situations that affect operations and security.

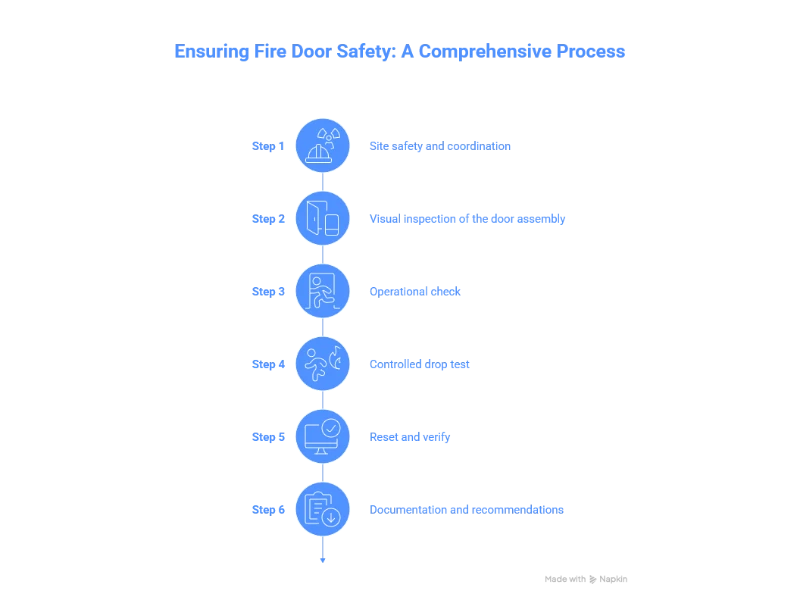

Our Fire Door Inspection & Drop Test Process

We keep the process structured, safe, and documented.

Step 1 — Site safety and coordination

We coordinate with your onsite point of contact to:

- isolate the door area

- control traffic through the opening

- plan the test without disrupting operations more than necessary

Step 2 — Visual inspection of the door assembly

We inspect:

- curtain/slats and bottom bar condition

- guides and alignment

- brackets and mounting hardware

- door path clearance

- signs of impact or wear

- any obvious mechanical issues

Step 5 — Reset and verify

After the test, we:

- reset the system

- restore normal operating mode

- confirm it functions correctly

Step 6 — Documentation and recommendations

You receive:

- a clear summary of results

- noted deficiencies (if any)

- recommended corrective actions

- practical next steps for maintenance scheduling

Step 3 — Operational check

We confirm normal operation first:

- smooth travel

- stable movement

- no binding or abnormal noises

Step 4 — Controlled drop test

We perform a controlled release test to confirm:

- door releases correctly

- door closes fully

- door remains stable during descent

- door seats properly at the bottom

- door doesn’t bind in the guides

- door is safe and predictable

What We Document (So It’s Useful to Facility Managers)

We focus on documentation that helps you, not paperwork for its own sake.

Typical documentation includes

- door identification (location, type)

- observed condition issues

- operational findings

- test outcome notes

- recommended repairs or adjustments

- maintenance suggestions to reduce repeat issues

If you manage multiple doors, we can provide a clear door-by-door summary.

What Affects the Cost?

Fire door testing is not priced like a residential service. Cost depends on:

Main cost factors

- number of doors

- door type and size

- access complexity and operating hours

- whether doors require minor adjustments during the visit

- documentation needs (single site vs multi-door facility)

We provide clear estimates and scope in writing.

For related commercial support, see

Repairs Often Needed After Failed Tests

If a door doesn’t pass inspection or drop testing, common fixes include:

- guide alignment correction

- hardware tightening and reinforcement

- bottom bar repair/replacement

- curtain/slat repair

- obstruction removal and clearance improvements

- release mechanism adjustments or repairs

- operator/controls troubleshooting (when connected)

How Long Does Fire Door Inspection & Drop Testing Take?

Timing depends on door count and site access.

Typical ranges

- Single door inspection + drop test: often 45–90 minutes

- Multiple doors: scheduled in blocks to reduce operational disruption

We plan around your workflow as much as possible.

How Often Should Fire Doors Be Inspected/Tested?

Requirements can vary by facility type and your compliance needs.

A safe, practical approach is regular inspection and scheduled testing as part of a facility maintenance plan.

Common scheduling approach

- Routine inspections at planned intervals

- Testing scheduled to match audit cycles and safety requirements

- Immediate inspection after impact damage or abnormal operation

If you tell us your building type and how many doors you manage, we can recommend a realistic service rhythm.

Alvin Scheduling Note (Operations Reality)

If your facility has shipments and deliveries, timing matters.

We can coordinate inspection windows to reduce disruption—especially for sites near busy corridors off Hwy 6 and Hwy 35 where bay scheduling is already tight.

Related Services

Facilities that require fire door testing often also need: